If you can’t see the forest for the trees, you may suffer from distracted management.

So many supply chain teams are operating with out-of-date policies, annual inventory counts mandated by internal and/or external auditors, competitive bid templates lacking adequate protection, and restricted staff training, or without monitoring supplier performance, having a contract management strategy, or being myopically focused on reducing costs.

When asked why, a common answer from department heads and front-line staff is that they are too busy “running a department to worry about whether a contractor has adequate insurance or not – it’s only a $5000 job! What could possibly go wrong?” Another frequently heard response is: “We’re too busy to get around to fixing it but we will – soon.” Soon never arrives, as it takes a backseat to tactical busy-work, such as Churning out RFPs under the illusion that the process will invariably lead to the best suppliers submitting the best proposals at the best price. This blind faith can lead to price fixing or collusion in the market. Smaller communities often are unaware that suppliers in the neighbouring communities won’t bid against each other – or will collude to skew the results or invite favouritism based on an address. Ensuring value for money is an imperative in any organization.

If you have heard these statements – you likely have distracted management setting priorities. These statements are not uncommon. The problem is, they perpetuate reactive situations based on tactical practices, rather than responses focused on strategic solutions.

I’ve gone into clients’ offices and talked to their procurement staff, our conversations often beginning with “So what are you working on?” and the common reply of: “We’re putting out a tender for copy paper” or “We’re getting ready to do our inventory count” or “We’re preparing for budgets” or “We’re getting ready for year-end.” These are good objectives – but they are also symptoms of distracted management.

The leading organizations are focused in eliminating paper; single-point data capture; rationalizing print devices; benchmarking against the number of print copies per staff person; and using milestones to measure progress. Daily cycle counts in large, small, private and public-sector organizations have been effective for around 25 years – yet many supply chain groups still conduct a draconian count of what is in stock and then wrestle with the inevitable discrepancies. This is a classic example of distracted management.

How do you know what you don’t know?

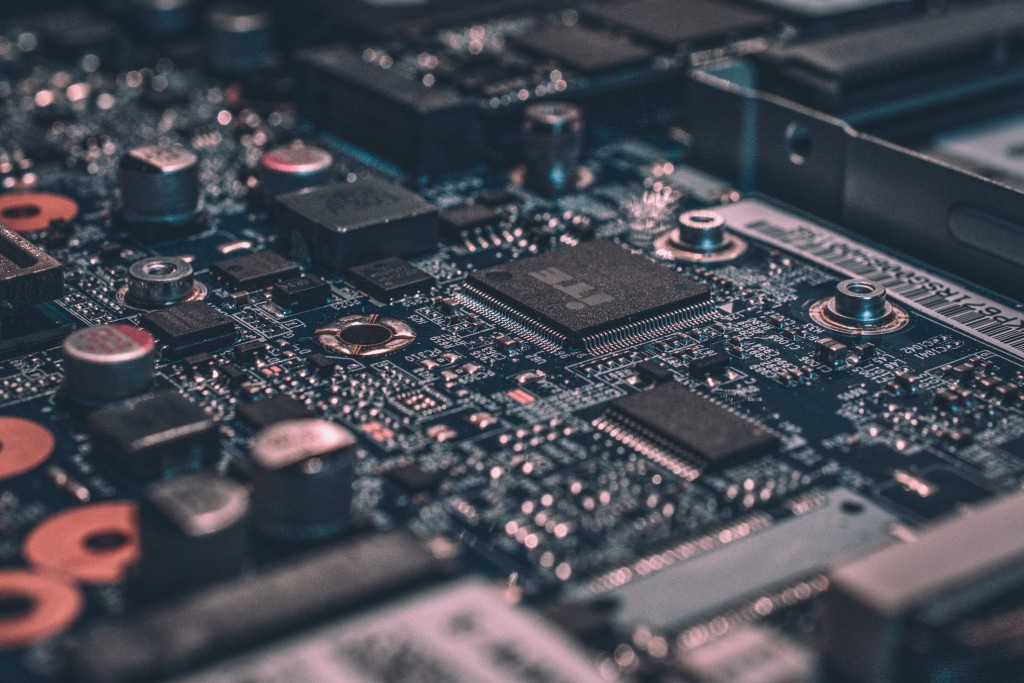

The speed of technology chafes against higher attrition through retirement and often leads to fewer heads and hands to do the work. There is a loss of knowledge transfer in the professional ranks. Hiring for competencies is a reasonable solution but typically only results in bringing the head count back to where it was, meaning that the way we are doing the work rarely changes.

Cooperative buying groups become trapped in contract cycles. While the work of issuing bids is spread among the members – the same repetitive sourcing tactics are deployed. Not a lot changes. Most of the ‘low hanging fruit related to price decreases’ was picked years ago yet bids are issued regularly for the same goods, often from the same suppliers left in the market, for marginal price concessions. By the time there are synergies gained between the end users and the new supplier, it’s time to go back to the market to try and squeeze further savings in the next contract cycle.

Few cooperative buying groups use a price index to measure their performance and to develop strategies. Supplier performance is almost a non-issue. A price-focused strategy of getting the lowest cost is the end game – period. Cooperative buying groups are tasked with finding annual savings against current budgets rather than best value. That’s what they know best. The tremendous opportunity to benchmark costs and processes available to public sector organizations is seldom considered – and one of the primary contributing factors is distracted management.

Lack of awareness of new technologies is a problem – we can’t plan for what we don’t know. Disruptive technologies such as bound metal deposition or intelligent quality systems affect cost structures globally. Are you adapting these? Others in the supply chain are.

Analytical methods such as activity-based costing studies (ABC) help to measure the cost of conducting business – administrative busy-work. Every organization should know the cost of issuing a competitive bid to ensure there is good value for doing so. If we have a good idea as to what the cost to issue a bid is, we have a good idea as to what our capacity is. When we want to find process savings, we now have a benchmark. Drafting templates designed for efficiency in process management makes economic sense. However, distracted management takes us away from these practices. We are too busy to get a template which meets the organizational needs due to the time it takes to put in the effort. We know it invites risk. This process works – until it doesn’t.

Leading organizations have relevant procurement key performance indicators KPIs, both financial and non-financial; use quality management techniques to improve practices; work with NGOs to affect value; make it easier for small medium enterprises to do business with them; use market sounding to assess competitiveness; prequalify contractors for efficiency; include the economic multiplier effect when assessing returns on investment; use qualification-based selection methods; use value-per-point evaluations; run integrated construction management strategies; utilize job order contracting software; involve fairness monitors to ensure good process management; develop contract management strategies; utilize constructability reviews to measure the probability for success involving construction; measure procurement’s performance against a price index; use vendor performance as a criteria; use total cost of ownership as a determinant of value; engage in social procurement; ensure a diverse supplier base; prepare for the circular economy; remain apolitical and professional; and look for leading practices on a continuous basis.

The cure for distracted management

Leading organizations realize that trying to do it all with in-house resources is a noble gesture but an impossible task, and so do not fall prey to distracted management. These organizations aren’t too humble to admit when they need help. They know they must have strategic objectives to ensure they are meeting their stakeholder expectations in principle and in practice. Leading organizations invest in the training of staff and provide the resources necessary for developing internal expertise and for learning from external expertise to stay current, competitive, and competent.

Larry Berglund